Perhaps they [the USAF] are waiting for the new radar that will start arriving in lot 17?

1. I think that might be the case for the USAF — they are at a steady state of converting squadrons to F-35As. With the amount of new FMS orders, there will be a ramp up sooner or later.

2. I suspect the USAF is vacating a few slots here & there, for some priority countries (like Finland & Poland), who are on the frontline with a Russian threat. There is no rush for the USAF, as they already have a large fleet of F-35As in service.

3. The USAF needs to fund the B-21 bomber and the Next Generation Air Dominance fighter, a slow down for 2-3 years makes sense, while waiting for software to mature & to upgrade older block 4s with the new AN/APG-85 AESA radar.

4. Again I suspect the AN/APG-85 AESA radar is a low hanging fruit from the Next Generation Air Dominance fighter, which is classified.

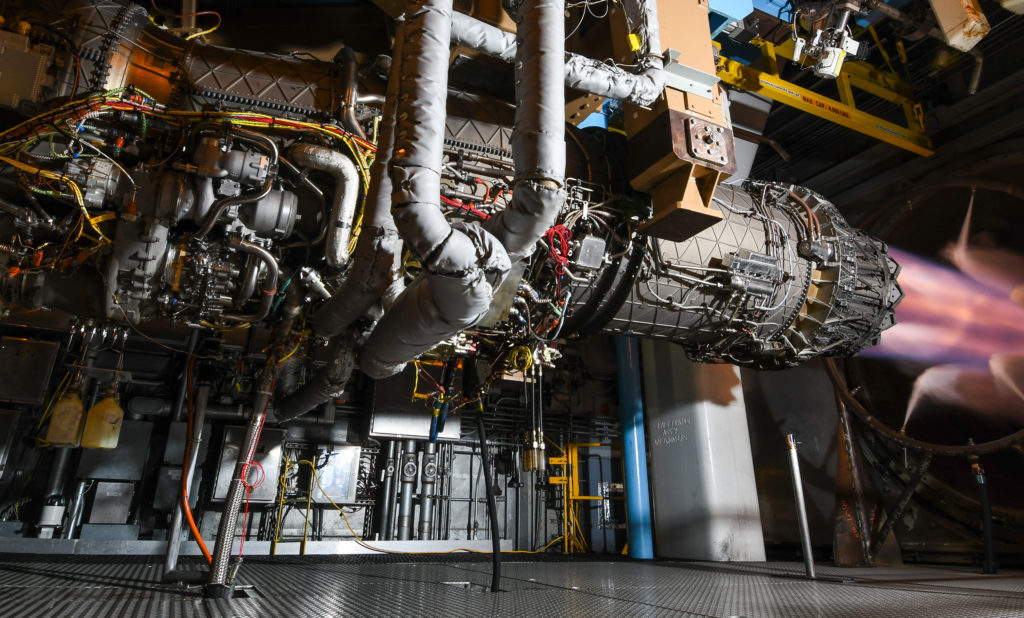

5. The F135 was designed to handle a 15 kilowatts cooling demand, but that requirement has already doubled to an estimated 30 kilowatts. Cooling air is generated primarily by pulling bleed air from the engine and running it through heat exchangers (see:

9 reasons why the F-35 needs a new engine).

- The F135 meets the 30 kilowatts demand by pulling more bleed air from the engine, which further reduces thrust.

- By the time Block 4 version of the F-35 is fully fielded in 2028, aircraft sub-systems will need a minimum of 47 kilowatts of cooling, and the amount required to meet follow-on capability demands range as high as 60 kilowatts.

- The performance and tactical effective range of subsystems like a new AN/APG-85 radar [PDF] and enhanced electronic warfare systems that will come with the F-35 Block 4 will require more electrical power. Add upgrades that are on the horizon like directed energy weapons, and you start hitting voltage stops.

- More than that the “first three increments of the [#F35] fighter’s Block 4 upgrade can function with the existing engine. Beyond that, we need to do something different. The jet can’t fully exploit Block 4’s capabilities without more power" said Lt. Gen. Eric Fick PEO F-35 (JPO) via: AF Magazine.

6. In view of the above, I speculate that the RSAF’s buy strategy may be, as follows:

- batch 1 — 4 x F-35B

- batch 2 — 2 x F-35B (lot 18)

- batch 3 — 4 x F-35B (lot 19)

7. I suspect the RSAF will IOC the 1st squadron with 10 or more F-35Bs in the 2032 to 2035 time frame. In the meanwhile, Singapore will mature its fighter VLO tactics to use the cooperative battlespace with the F-15SGs while under the control of the G550AEW — with an upgrade of the F-15SGs in the late 2030s (with even more cooling and power), to keep them current to threats. By 2035, the RSAF’s F-35Bs can run primary or hand-off the missile strike to F-15SG.

8. The Pratt F135 engine was the only major F-35 sub-system that failed to cut its acquisition costs to reach weapons system program targets, which made bringing the cost of the F-35A below its US$80 million target that much more challenging.

9. Having Pratt and GE compete side by side for future engine contracts will force both to maximize the performance and minimize the cost of their engines.

10. I suspect that there is incentive to wait for a block 4, F-35A, in the 2036 to 2039 period, with:

- an AN/APG-85 AESA radar; and

- a GE engine from the Adaptive Engine Transition Program (if the USAF selects it).

11. To help the RSN secure our SLOCs, the RSAF badly needs a 2nd F-35A squadron with more range, given that the

combat radius of all three variants some 15% below the program’s objectives.

12. The F-35 needs a more powerful, fuel-efficient engine.