If it gets used that much, they will acquire another one. I wouldn't be surprised if that eventually happens.

A lot of these type of investments companies are often hesitant to make such capital investments where none have existed in the country before. However, once government accepts the risk, in terms of national interest, then such investments can be augmented and replicated. Again, most of the risk comes from the government itself, so it makes sense to show in terms of commitment to an industry or a project this kind of investment.

There was a significant investment in a large titanium mills for the F-35 production in Australia.

BAE Systems Australia has officially opened its new $10 million titanium machining facility at Edinburgh Parks, South Australia which would fabricate

www.australianmanufacturing.com.au

Its these kind of investments that need to occur to increase Australian content in ships, submarines, aircraft etc. Also sovereign capability is extremely important. As Covid showed, when the STHF, these types of precision, expensive complex machines are just simply impossible to buy. There are global bottle necks on how many can be produced, and bigger and stronger forces will prevent export and limit export of the production capability. Case in point, Italy is currently prohibiting the export of the AZ vaccine to Australia. Vaccines are relatively easy to produce (particularly the AZ one) and we can see that even the EU will tear itself apart over them. Australia can produce the AZ one currently but we are investing over a billion to be able to produce newer types in the future, for our region. Masks and PPE was another.

www.aumanufacturing.com.au

We need the machines to make machines.

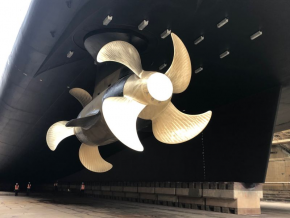

So one can imagine in a global conflict scenario, getting machines or their output would be near impossible. Fleets will be stuck in port, squadrons grounded, and production lines halted. Propellers are always highly valued as they can easily be damaged (think about one hitting a shipping container, or a rock). They can take months to mill out. Even a repair can be lengthy.

Inevitably these machines find commercial uses, milling plastic molds, steel press molds etc. This feeds into the economy. We did this before, back in the late 40's and early 50's, and that investment paid off every day for over 70 years.

Capability to fix podded propulsion will mean future cruise ships owned and operated in Australia can utilize this tech and know there is local know how to sustain and operate.